1949

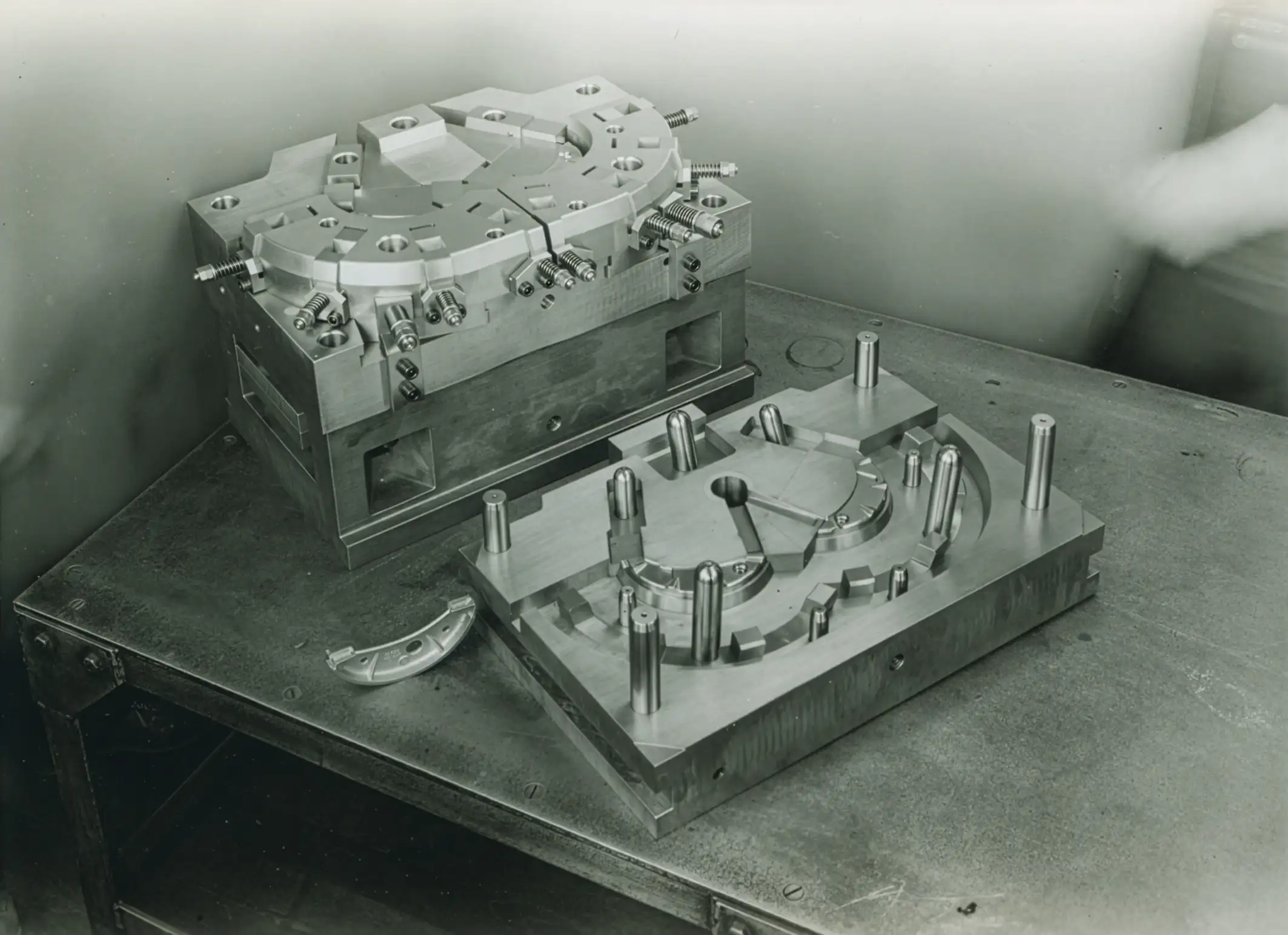

The diecasting workshop for casting and injection molding dies is founded on the ground floor of the family home. Here, casting and plastic injection molding dies are produced.

As a modern company with an experienced, dynamic team, we want to broaden the diecasting market, take innovations into series production and use our know-how for smart and efficient solutions. With a team of approximately 40 employees, state-of-the-art technology covering 3,000 m² and high-end machines from development, through production, to quality control, castFEX boasts the ideal framework for meeting your requirements.

Our pledge:

“We make diecasting-ready and future-proof components – efficiently and reliably.” With state-of-the-art technology, in-depth process know-how and practical support, we ensure project goals are achieved, from the prototype to series production.

In our Technology Center, we demonstrate diecasting’s full potential and empower both beginners and experts to proficiently and confidently

manage the entire process chain.

As an innovation driver, we set new standards, turn developments into series-ready outcomes and create sustainable solutions that shape

technological progress in the field of diecasting.

The diecasting workshop for casting and injection molding dies is founded on the ground floor of the family home. Here, casting and plastic injection molding dies are produced.

Production of the first dies for BMW and Bauknecht.

In an old barn in Schorndorf-Weiler, the light metal foundry Moneva GmbH + Co. KG starts production; it manufactures series cast parts for the automotive industry from the very outset.

The Moneva production site relocates from Weiler to Lederstraße in Winterbach, where it moves into the newly-built, modern diecasting foundry building.

The training department is first founded and then gradually expanded. A separate hot-chamber technology center is also set up for in-house trials and practical training offerings.

Remstal – where tradition meets the future. Die technology and training have shaped FRECH from the very beginning. In Winterbach, these core areas of expertise are pooled together and taken into a new era – a clear commitment to the company's origins, to quality and to the future.

6 machines with associated peripherals

Pooling many years of experience from the MONEVA series production foundry, FRECH die technology and FRECH training courses has created a high-performance partnership that provides innovative, precise and future-focussed solutions from a single source.

Interiors, electronics, EV motors

Entertainment, fashion, electric tools, domestic appliances, toy motors

Bathroom fittings, window/furniture fittings

Joining technology, medical technology

Tablets, smartphones, notebooks, casings

Would you like to make a career change? Are you looking for a new challenge?

All the current job vacancies are shown here.

We also welcome unsolicited applications at any time.

Get in touch now.